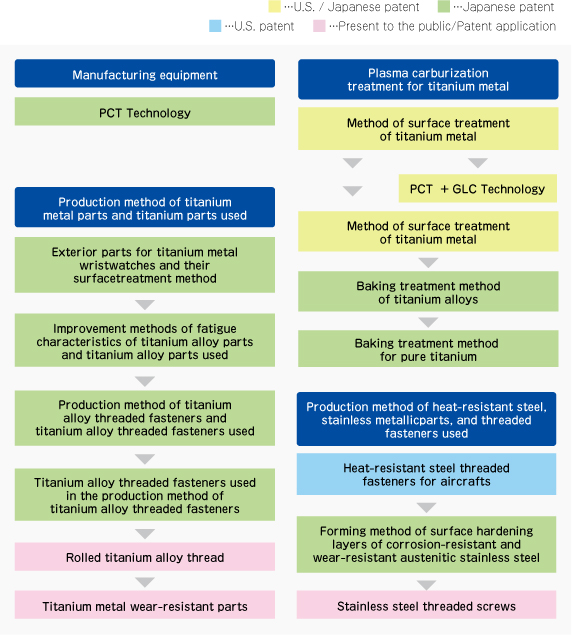

Threaded screws are the most basic of machine elements. In both Japan and the United States, we possess much proprietary technology that has been developed from the needs of the aerospace industry.

We are certain that much of this proprietary technology is contributing to many industries and license patents such as those for soft assets.

The SDC-PCT treatment is distinguished by a relatively low temperature process with less O2 present in the furnace resulting in metals highly resistant to wear and free of galling.

The SDC-PCT treatment is distinguished by a relatively low temperature process with less O2 present in the furnace resulting in metals highly resistant to wear and free of galling.Inside the SDC-PCT vacuum furnace,pulsed DC current of several hundred voltage is applied between the work-piece(cathode) and the chamber(anode).

SDC-PCT is performed in glow plasma,which is ionized hydrocarbon-containing gases by pulsed by pulsed DC.

The SDC-PCT treatment demonstrates its superiority over existing PCT processes by producing metals which are highly resistant to wear and galling free.

SDC Tanaka created a furnace for this new heat treatment process, which can be operated from a personal computer.

The process is easy to use , effective , and environmentally friendly due to using plasma in vacuum furnace that is complete in processing cycles without emission of gasses such as Co2.

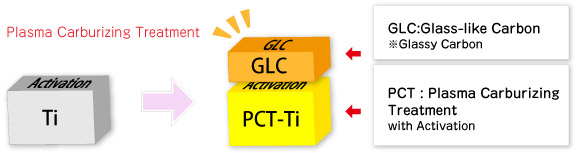

(PCT:PlasmaCarburizingTreatment)

(GLC:Glass-likeCarbon)※GlassyCarbon

(GLC:Glass-likeCarbon)※GlassyCarbon

"Plasma-carburizing" is one of the plasma surface diffusion process in the vacuum and significantly improves wear resistance by producing high hardness layer.

We have developed that a GLC film formed on the carburized titanium surface at the same time.

Our newly combined surface modification technique are very effective for improvement of corrosion resistance, wear resistance, lubricity (low friction coefficient), releasability, gas impermeability and biocompatibility in titanium and its alloy.

We have developed that a GLC film formed on the carburized titanium surface at the same time.

Our newly combined surface modification technique are very effective for improvement of corrosion resistance, wear resistance, lubricity (low friction coefficient), releasability, gas impermeability and biocompatibility in titanium and its alloy.

The outline of PCT+GLC

The main feature

By giving titanium metal PCT, a harder GLC

layer is formed over the hard PCT laye