SDC Clean-Bolt Series

SDC Clean-Bolt Series

It is only one proven technology in the world.

No lubricant grease or oil, Ag (silver) plating nor dry film lubricant are required to prevent galling.

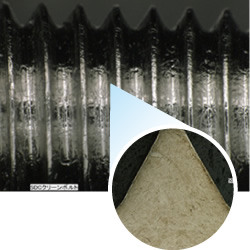

Stainless steel fasteners are particularly susceptible to thread galling.

During the tightening of the fastener, pressure builds between the contacting and sliding thread surfaces and breaks down the protective oxide coatings. With the absence of the protective oxide, interface metal high points shear or lock together. In the extreme, galling leads to seizing and welding.

SDC Clean bolt is the most effective fastener to withstand wear and galling, while meeting corrosion resistance, when there is need for cleanness as in semiconductor devices or sanitation as in food or pharmaceutical processing, which precludes the use of lubricants.

During the tightening of the fastener, pressure builds between the contacting and sliding thread surfaces and breaks down the protective oxide coatings. With the absence of the protective oxide, interface metal high points shear or lock together. In the extreme, galling leads to seizing and welding.

SDC Clean bolt is the most effective fastener to withstand wear and galling, while meeting corrosion resistance, when there is need for cleanness as in semiconductor devices or sanitation as in food or pharmaceutical processing, which precludes the use of lubricants.

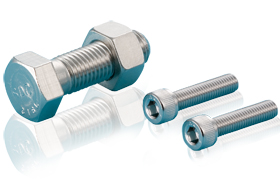

Hex Socket Cap Screw

Hex Socket Cap Screw Hex Bolt, Hex Nut

Hex Bolt, Hex Nut

Applicable Industries

(1)

Semiconductor, FPD and Solar Panel

(2)

Pharmaceutical and Cosmetic Chemicals

(3)

Food and Beverage etc...

(4)

Hard disk drive

Features and Benefits

(1)

No risk of contamination generated by lubricant, coating and plating

(2)

Extends life of frequently screwed fastener and reduces damage on equipments fastened

(3)

Eliminates idle time of maintenance and assembling process by "galling" fastener after heating and cryogenic process cycles (recommended to use under 300 ºC or 572 ºF)

(4)

Maintains good corrosion resistant and nonmagnetic properties

(5)

Available in a wide range of fastener type and size

(6)

Other materials are available upon request

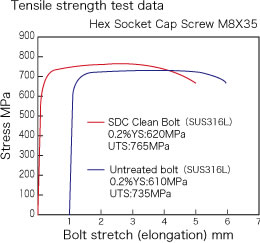

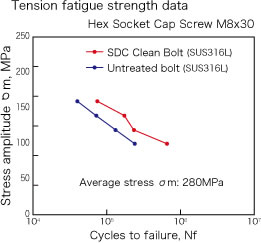

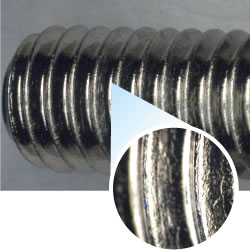

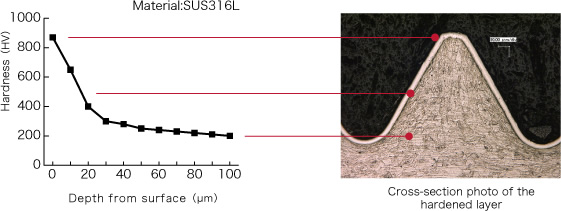

Enhanced mechanical properties by SDC Plasma Surface Treatment

Tensile strength |

Fatigue strength |

|

|---|---|---|

|

|

Material: S31603(316L)

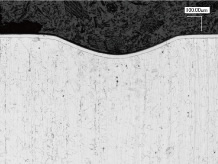

Material: S31603(316L)There is no crack nor peeled in case

hardened layer despite the base mate -

rial was plastically deformed with high

load impact. The case hardened layer

followed the base material deformation.

hardened layer despite the base mate -

rial was plastically deformed with high

load impact. The case hardened layer

followed the base material deformation.

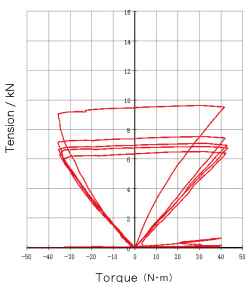

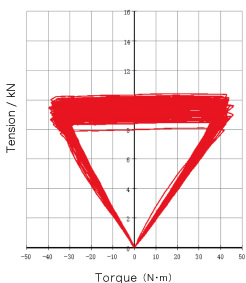

Thread Anti-Galling During Tightening

Untreated bolt |

SDC Clean Bolt |

|

|---|---|---|

Untreated bolt galled and broke after |

SDC clean Bolt has no problems after |

Comparison of SDC Clean Bolt with silver plated bolt

Comparison table

| Silver plated bolt | SDC Clean Bolt | |

| Preventing galling | 〇 / Good | ◎ / Excellent |

|---|---|---|

| Oxidation resistance | × / Poor | 〇 / Good |

| Storage in ambient air | × / Poor | ◎ / Excellent |

| Repeated use | 〇 / Good | ◎ / Excellent |

| Resistance to surface peeling |

× / Poor | ◎ / Excellent |

| Free of silver contamination | × / Poor | ◎ / Excellent |

| Conductivity | ◎ / Excellent | 〇 / Good |

| Silver plated bolts have problems with the plated film peeling and with atmospheric oxidation (discoloration) |

The SDC Clean Bolt can be used repeatedly without peeling and does not oxidize |

|

Condition of the threaded area after ten cycles of tightening and loosening

Silver plated bolt |

SDC Clean Bolt |

|

|---|---|---|

Peeling of the silver-plated surface was observed |

There is no risk of contamination by peeled plated surface thanks to the diffusion-based surface hardening technology |

Condition after storage in the ambient air (90 days indoors)

Silver plated bolt |

SDC Clean Bolt |

|

|---|---|---|

Oxidation occurs in the silver-plated area |

No specific storage method is required |

Product Information

Material:

SS316 (S31600) or SS316L (S31603)

(Other materials are available upon request)

(Other materials are available upon request)

Surface Treatment:

SDC plasma surface-hardening process

Options (available upon request):

Vent hole for vacuum chamber

Extra precision cleaning and packaging for clean room

ANSI, DIN and other standards

Non standard customer designed parts according to engineering drawing

Extra precision cleaning and packaging for clean room

ANSI, DIN and other standards

Non standard customer designed parts according to engineering drawing

Item Description in Metric:

Hex Bolt, Hex Nut

Hex Socket Cap Screw

Hex Socket Set Screw

Hex Socket Cap Screw

Hex Socket Set Screw